Visual Testing

Visual Inspection, also known as Visual Testing (VT), is the oldest, most versatile, and most commonly used non-destructive test (NDT) method.

Ultrasonic Testing (UT)

Ultrasonic Testing (UT) uses high frequency sound energy to conduct examinations and make measurements. Ultrasonic inspection can be used for flaw detection/evaluation, dimensional measurements, material characterization, and more.

Magnetic Particle Testing (MT)

Magnetic Particle Testing uses one or more magnetic fields to locate surface and near-surface discontinuities in ferromagnetic materials

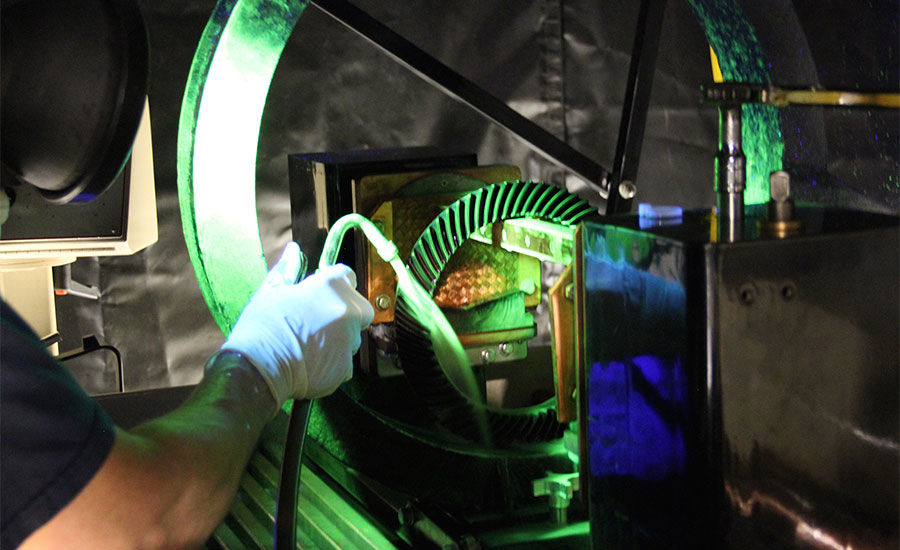

Dye/Liquid Penetrant Testing (PT)

This involves applying a liquid dye to the surface of a material and leaving the dye to “dwell” on the surface for a pre-determined period of time. The liquid can be either a colour that is easily visible under normal lighting conditions or a yellow/green fluorescent colour thatrequires special lighting conditions to be seen effectively.

Radiographic Testing (RT)

Radiographic Testing (RT) is a nondestructive examination (NDE) technique that involves the use of either x-rays or gamma rays to view the internal structure of a component

Positive Material Identification (PMI)

Positive material identification (PMI) is used to analyse and identify material grade and alloy composition for quality and safety control

Hardness Testing

Hardness testing makes it possible to determine material characteristics such as strength, ductility and wear resistance. It also shows whether the heat treatment process has been carried out properly